How It Works

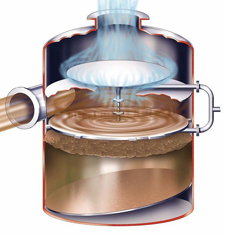

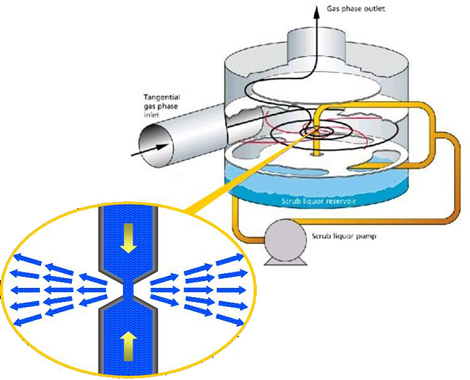

The diagrams and video animation below explain the operation of the V-tex® technology.

Key Benefits

The V-tex® offers robust operation, using even dirty and solid-laden liquor streams, making it the scrubber of choice for arduous applications and where high availability, low maintenance operation is essential.

- High availability and minimal clean-out costs as no internals to foul

- Consistent, predictable mass- and heat-transfer rates provided by self-cleaning, non-clogging nozzle

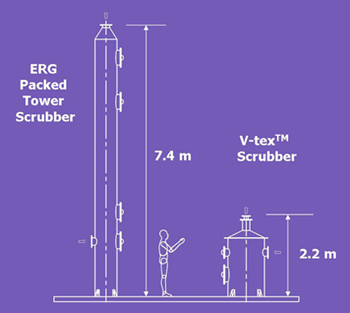

- Low installation costs, especially when retrofitting into existing buildings, because of low height

- Smaller volumes of spent liquor to be sent to waste as V-tex® can scrub with viscous liquors and slurries

- High efficiency performance irrespective of gas flowrate means no narrow window of operation limiting your production cycles

- Proven in a wide range of applications

Key Features:

- Opposed jet nozzle in centre of chamber

- Fine droplet spray pattern for high mass transfer

- Induced swirl from tangential gas inlet and central gas outlet

- Integral sump separated by lower chamber plate

- Droplet elimination by spray plate

Applications

V-tex® technology is widely used for challenging environments such as:

- Difficult scrubbing applications often with recovery and/or manufacture of saleable bi-product

- Stripping of contamination from liquor/slurries and recovery

- Condensing particularly when the gas/steam has suspended particulate

For applications where the scrubber height is important, such as pharmaceutical and microelectronics production, the V-tex® is able to fit on a single storey. The diagram shows an example of a packed tower and V-tex® scrubber both sized for 1,000 m3/hr and 99.5% removal of HCl.