Metal Finishing

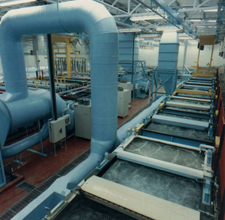

ERG's purpose-designed scrubbing systems are engineered to suit each application and client's requirements.

ERG has experience of treating air pollution problems from a range of metal-industry sources. These include:

- Surface preparation

- Strong alkali solutions for surface cleaning

- De-smut and key-up the surface using low concentration nitric acid

- Anodising

- Hot sulphuric acid dips

- Degreasing

- Aluminium smelting

- Steel scale cracking

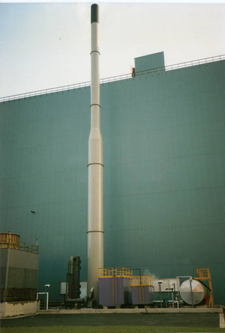

ERG's systems include for tank extraction and lip-ducts, air extraction ductwork, scrubbing towers and VOC removal.

The air pollution treated in these systems includes:

- caustic fumes

- acid fumes - sulphuric acid fume, phosphoric acid fumes, nitric acid fumes

- degreasing solvents

- scale particulate

- HCl, SO3, NO2

All ERG's systems carry a process performance guarantee and allow the user to demonstrate both IPPC compliance, and achieve a working environment consistent with the COSHH requirements (EH40 guidance) within the factory and external to it.

Our client-base includes Avesta, Shorts Brothers, British Steel, Corus, Alcoa, Yuasa Batteries, Rolls Royce.

Quality and certification

All ERG systems are designed and manufactured to ERG's ISO9001 Quality Management System.

Our systems are typically built to good engineering practice, though where required, we can design and build to be CE marked as required to the Pressure Equipment (97/23/EC) and ATEX (94/9/EC) Directives. Vessels can be supplied in accordance with PD5500, BS4994 or ASME VIII.